LANDAUER provides flexible dosimetry solutions. You may choose:

OSL is ideal for small laboratories and hospitals processing dosimeters in-house to full service dosimetry laboratories providing personnel services throughout the world.

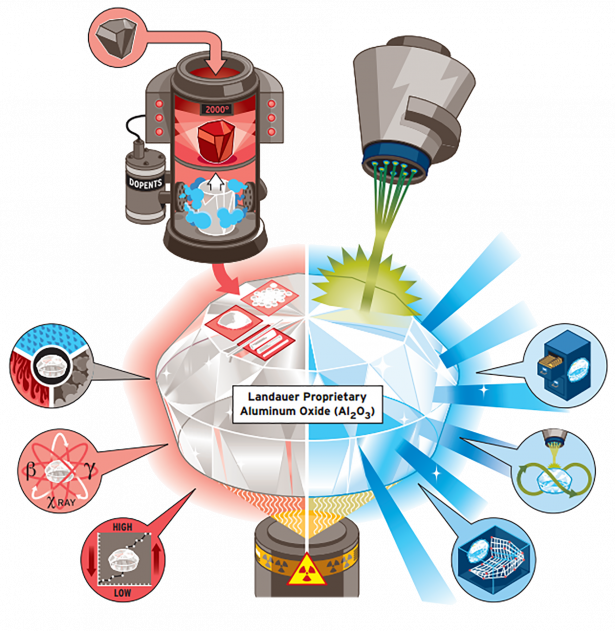

LANDAUER exclusively manufactures OSL aluminum oxide (Al2O3:C) crystals using a proprietary process. High purity aluminum oxide is melted at high temperatures and recrystallized in order to introduce Carbon dopants and oxygen vacancies. The dopants and vacancies dictate the OSL properties of the radiation sensitive Al2O3. LANDAUER uses custom designed furnaces to precisely control the process necessary to produce aluminum oxide crystals for radiation measurement.

LANDAUER’s proprietary method of manufacturing creates a variety of crystal configurations and provides a platform from which many detectors can be produced.

The manufacturing process allows the crystals to be grown into various shapes depending on the intended applications.

OSL aluminum oxide technology has critical advantages over thermo-luminescence (TLD) one such as:

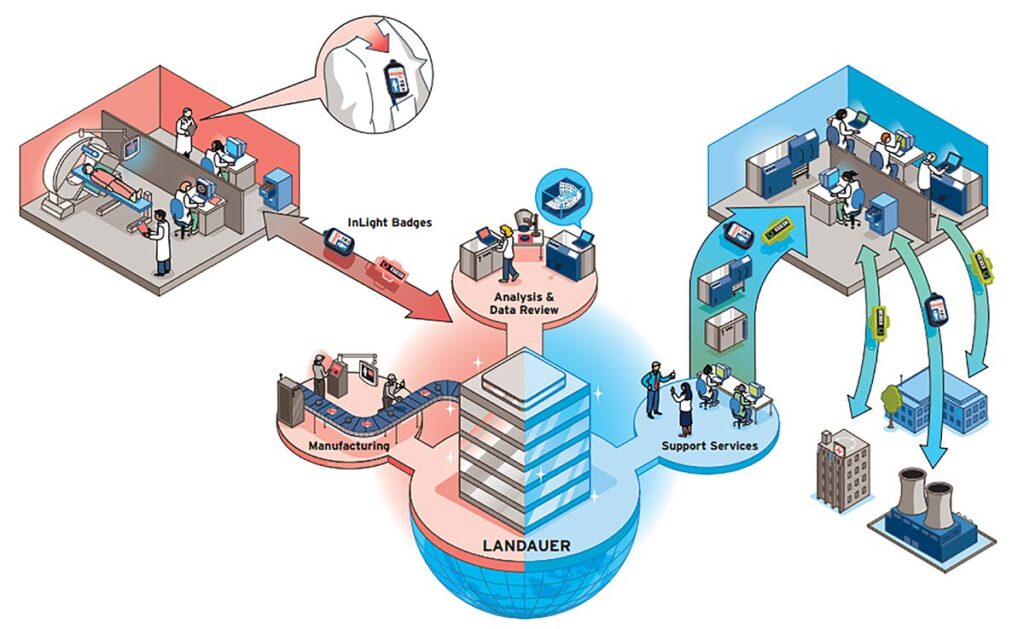

LANDAUER dosimeters proposes several types of dosimeters depending on the applications. INLIGHT dosimeters are the most common one.

The dosimeters are manufactured and quality checked in LANDAUER factory.

INLIGHT dosimeters can be used and easily customized for personnel monitoring, area monitoring, emergency response or other specialized service.

Dosimeters identification is made easy with the labels and barcode supplied.

Sensitivity is traceable from detector serial number.

The different OSL readers are designed by LANDAUER.

OSL aluminum oxide technology benefits the following advantages:

INLIGHT dosimetry monitoring system are simple to set up and to operate. The design has been improved regularly based on our experience operating our own accredited laboratories with the goal to improve accuracy, reliability and productivity.

Setting up and operating a dosimetry laboratory, it offers the following benefits:

High sensitivity minimizing the stimulation: the optical stimulation keeps more than 99 % of the information. The non destructive readout process of OSL Al2O3:C detector enables dosimeters to be archived and allows multiple reading in case of dose investigation. The detectors can be reused several years.

With 200 laboratories using InLight technology worlwide, LANDAUER has built a strong experience supporting his customers.

With 200 laboratories using InLight technology worlwide, LANDAUER has built a strong experience supporting his customers.

Our engineers benefit the experience acquired by LANDAUER operating its own dosimetry laboratories.

Our technology evolves with the release of new regulation and new standards. We participate in the committees elaborating the new release of IEC and ISO standards.

To support our customers during laboratory equipment lifetime, LANDAUER proposes them the typical following maintenance contract: